Please visit us at Fruit Focus at NIAB EMR, East Malling, Kent on 19th July 2017 on stand number 357.

Please visit us at Fruit Focus at NIAB EMR, East Malling, Kent on 19th July 2017 on stand number 357.

Micron Group would like to celebrate 30 years of service by David Denton who joined the company in February 1987.

David is a key member of the Micron R&D Department and has more recently take a more active role in technical sales, directly supporting our Group Sales Director, with particular reference to the Varidome and Enviromist product ranges.

The Directors of Micron Group would like to congratulate David on this milestone and look forward to the next 30 years!

Micron Group would like to celebrate 40 years of service by Dawn Haynes who joined the company in September 1976.

Dawn is a key member of the Micron Production department responsible for the assembly of the company’s innovative hand-held spraying equipment such as Ulva+ and Handy range of sprayers, many of which are exported all over the world. The company also manufactures an ever expanding range of tractor-mounted equipment which can be used locally for weed control in strawberry tunnels and cider apple orchards.

Dawn is currently the second longest serving employee at Micron and her input over the years has contributed greatly to the success of the business. The Directors of Micron Group would like to thank Dawn for her dedication and hard work and look forward to working with her for many years to come.

IMAGE: Photograph taken during celebrations of Dawn’s 40th Anniversary

Micron Group have announced the launch of Micron AU9000, a new vehicle-mounted sprayer for public health applications. The cold fogger has been specifically developed for the control of adult mosquitoes, flies and similar pests using both conventional and waterbased ULV insecticides.

The AU9000 provides excellent control of spray droplet size and flow rate of insecticide, whilst being easy to operate and maintain. It is intended for use by municipalities, pest control contractors, military authorities and similar organisations requiring reliable, cost-effective pest control.

The sprayer uses a reliable 10 HP Briggs & Stratton four-stroke engine, driving a powerful 180 m3/hour blower. The two sprayheads can be independently oriented both horizontally and vertically to achieve a wide swath width and to provide optimum coverage of the target.

All controls are operated from inside the vehicle cab for maximum operator safety. The sprayer incorporates many unique safety features, including an air pressure sensor to stop the insecticide pump in the event of the engine stopping or a failure of the blower.

Insecticide is delivered to the sprayheads by a positive displacement gear pump with an electronic controller. A ten position switch on the control box in the cab to select the flow rate ensures precise and repeatable calibration.

Commenting of the new launch, Haydn Beddows, Group Sales Director said: “Fully compliant with WHO specifiations yet competitively priced, the AU9000 vehicle-mounted cold fogger will enable us to strengthen our position in the public health sector and access new geographical markets.”

Giant Hogweed, labelled as the “UK’s most dangerous plant”, has become a major issue that calls for immediate action. First introduced as an ornamental plant in the 19th century, this highly invasive and prolific plant has been usurping Britain’s countryside and has become a particular problem near riverbanks, roadsides and railways. Not only does Giant Hogweed compete with the native species but it is highly toxic and can cause serious burns and blistering to people and animals upon contact with its poisonous sap.

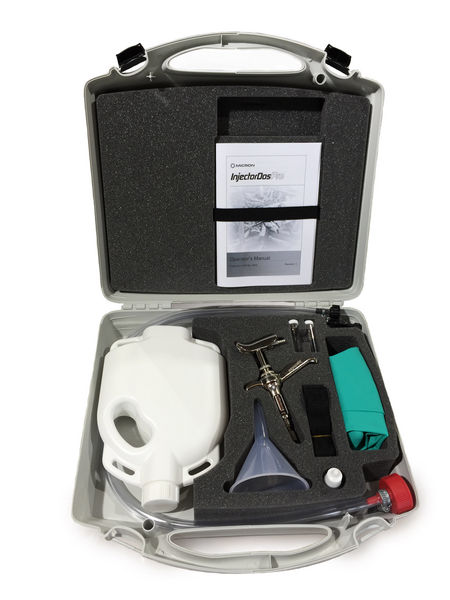

Micron Group, a leading manufacturer of precision sprayers and applicators, offers a simple yet highly effective solution to this problem. Specifically developed for tackling hollow-stemmed weeds such as Giant Hogweed, Micron’s InjectorDos Pro is a metered-dose stem injector that can deliver a lethal dose of herbicide directly into the stem, allowing for the active ingredient to get rapidly translocated into the root. InjectorDos Pro is safer for both the operator and the environment compared with conventional spraying as there is no risk of spray drift or contamination of soil and watercources. As such, InjectorDos Pro is ideally suited for use near river banks or adjacent to surrounding vegetation which needs to be preserved.

Working with InjectorDos Pro is easy. Its ergonomic and compact design allows better access to the base of the weed which will be particularly appreciated by users when injecting dense or difficult to reach plants and working on uneven terrain such as riverbanks, ditches or roadsides. InjectorDos Pro is made from stainless steel and is ergonomically shaped to reduce fatigue. The applicator’s trigger requires a minimal amount of pressure to operate thus minimising the risk of repetitive strain injury.

The InjectorDos Pro ‘dial-in’ facility allows operators to dispense a pre-determined metered volume of herbicide formulation between 0.1ml and 2ml per shot. The herbicide is injected directly into the hollow stem of the plant through a robust needle which penetrates the walls with minimal effort. A second shorter and finer needle is provided for smaller shoots and follow on applications. Generally a single 2 ml shot of neat glyphosate is injected into each stem for best results. Giant Hogweed is easiest to treat whilst in its flowering stage before the seeds ripen as this will also translocate the active ingredient into the seed and render it non-viable.

Aimed at the professional user, InjectorDos Pro comes complete with a compact one litre backpack, shoulder strap, funnel and a pair of gloves, all packed in a comfortable carry case.

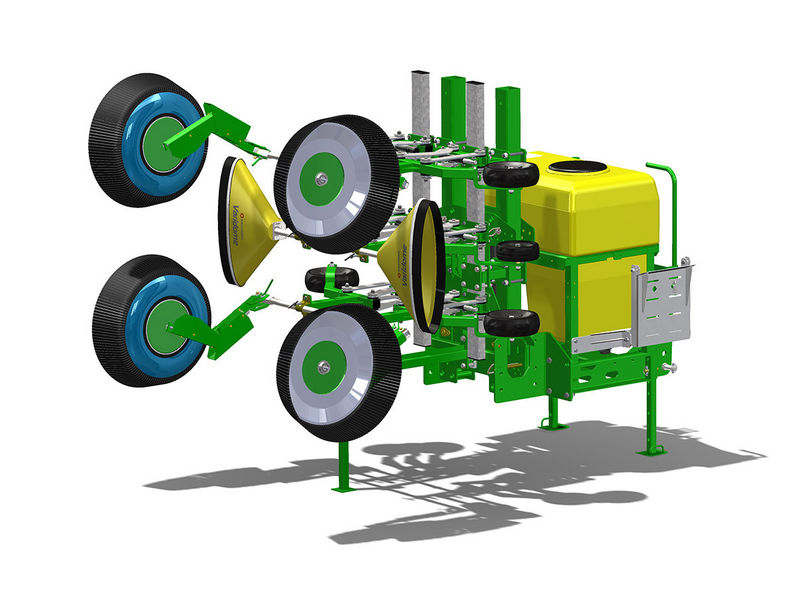

Manufacturers of precision spraying equipment, Micron Group, have appointed two new dealers in the UK for the Varidome range of band sprayers. Challis Reed Ltd will be responsible for Varidome sales and service in East Anglia whereas John Rhodes AS Ltd will look after the Central region.

Commenting on the new appointments, Toby Whatley, UK Sales Manager at Micron, said: “Since the launch of the first commercial unit in 2010 as a three metre wide sprayer, the Varidome developed into a complete range of highly technical, user-tailored spraying solutions capable of treating up to 12 metres in one pass and simultaneously applying multiple products. With a 3 star LERAPs rating and proven 95 per cent plus drift reduction, Varidome provides farmers with an alternative method of weed control where the conventional approach is failing and has proven to both improve spraying results and cut costs, accounting for the sprayers’ fast uptake amongst growers. We are pleased to announce the appointment of John Rhodes and Challis Reed, two highly respected names in agriculture as our new Varidome dealers. Having the brand represented by these knowledgeable companies will allow us to have close contact with the end user in order to continue with our tailored approach, as well as offer a fast, reliable and personal service.”

Micron have appointed Yorkton Aircraft Service in Yorkton, SK as a distributor for Micronair atomisers and other aerial spray equipment in Canada. This was announced at the Canadian Aerial Applicators Conference in Winnipeg in February 2015, where Yorkton had a booth and display of

Micronair atomisers. Micron’s Technical Manager also participated and was on hand to advise current and potential users of Micronair equipment.

Commenting on the recent appointment, Haydn Beddows, Micron Group Sales Director said “We are delighted to have Yorkton Aircraft Service as our new distributor and we look forward to working with Cheryl and Allan Denesowych and their team to support our customers in Canada. We plan to work closely with Yorkton and we look forward to participating in their spray calibration clinic which is taking place week commencing 25th May 2015.”

See www.yorktonaircraft.com for more details.

Micron Group, manufacturer of low volume precision sprayers for agricultural, horticultural and amenity applications have recently had their Enviro range of shielded equipment assessed for LERAP (Local Environmental Risk Assessment for Pesticides) Low Drift status by the Chemicals Regulation Directorate. Micron Varidome, Spraydome, Undavina and Spraymiser sprayers (both CDA and HiFlo models) have all achieved a three star LERAP accreditation – the highest rating currently available in the UK – which recognises the sprayers as a DRT (Drift Reducing Technology) with proven drift potential reduction of over 75 percent.

The extensive wind tunnel testing carried out in conjunction with Silsoe Spray Applications Unit to support the LERAP application had shown that the shields actually have the potential to reduce spray drift by over 95 percent.

Commenting on this achievement, Tom Bals, Chairman at Micron, said: “Ever since the inception of our company in 1954, targeted pest control has been at the heart of our business. For decades our research and development efforts have been dedicated to reducing the environmental impact of pesticides through innovative technologies with a particular focus on low volume application – initially via atomisers and sprayers using Controlled Droplet Application technology invented by Micron which is also a DRT. Current demands require increasing precision of product placement through careful spray system selection and our newly developed range of shielded DRT sprayer systems offers users major commercial benefits in terms of targeted application and economy of pesticide usage.”

Micron has recently introduced Varidome 100HiFlo and Varidome Hybrid models for onions and asparagus respectively – innovative, easy to use band sprayers that enable farmers to reduce their herbicide and water usage, cut costs and improve weed control – whilst being better for the environment. Simon Stockdale from Sandfields Farms Ltd reveals why Varidome is their preferred choice for weed control…

“Sandfields Farms Ltd is owned by G’s and we are based in Warwickshire and Worcestershire. I drive innovation within the business and we have bought 3 Varidome machines, two for asparagus and one for salad onions. In Warwickshire, we grow 400 hectares of salad onions and 200 hectares of asparagus along with approximately 250 hectares of legume crops. We also grow 200 hectares of salad onions in Kent through The Lettuce Company and I am the general manager of this business. G’s Growers, the PO, have purchased a fourth Varidome that we operate in Kent in the salad onions.

I started working with Micron on the first Varidome sprayer for asparagus nearly three years ago. There was no other company offering what Micron did. We wanted a machine for weed control post-harvest (in June) without getting chemical onto the asparagus foliage. Up until the point we have finished harvest we are not able to control any weeds by which time we have problems with thistle and mare’s tail – both of which are very hardy plants. However, at this time of year the asparagus fern is very soft and sensitive to any application of chemical which meant we were having to hand weed areas of this crop which is very costly.

With Micron’s Varidome machine, we are now able to control weeds under the asparagus canopy, right up to the base of the asparagus plants and over the entire contour of the beds by using 3 different domes set at different heights. With the nature of the high clearance of the Varidome shields, we are able to subsequently make second applications when the fern is high, with little or no damage to the fern.

In 2014, Micron advised me of the new narrow Varidome 100HiFlo shields and we started considering a machine fitted with the narrow shields for use within our onion crop. We are mindful of the fact that we will be losing some valuable weed control chemicals in the next year or two and that the alternatives, when trialed, were very hot on the crop and led to leaf damage.

With the Varidome 100HiFlo, we are able to apply these chemicals directly onto the weeds without contact onto the flag leaf and subsequent crop damage, whilst achieving good control.

We were also hand-weeding certain problem areas within the onion crop as we couldn’t control them when the crop was established with an overall spray. Using Varidome 100HiFlo means we no longer have to do this, saving us both time and money.

Due to Varidome’s flexible design, we can raise the shields to allow us to apply tebuconazole (fungicide) to the base of the plants rather than the overall flag leaf. We are also looking at using higher application rates of chemical in between the rows and a lower dose rate on the actual crop by using the Micron Dual Spray Tank we have purchased. The dual tank will also be used to apply a fungicide and an herbicide at the same time reducing the number of passes we are required to make.

Furthermore, the Varidome has also increased the window of opportunity for us to spray the crops as it is not affected by wind. We looked at alternative machines and were of the opinion that Micron offered a good quality build of the machine and a much more advanced parallelogram system on the individual carriages with the narrow domes. The unique rubber shrouds on the bottom of the shields could not be matched by any other manufacturer either.

We estimate all the four machines will have paid for themselves within two years.”

Simon Stockdale, Sandfields Farms Ltd

Precision sprayer specialists, Micron Group have announced they would be launching not one but two new sprayers at this year’s Cereals event (Stand 111) which is set to take place at Boothby Graffoe, Lincolnshire on 10-11th June 2015. Specifically, farmers and industry professionals will be able to see the Varidome S3 100HiFlo model for cereals and Varidome S3 Hybrid complete with Micron’s Modular Tank System for work in asparagus.

Backed by years of research and development, Varidome S3 100HiFlo represents the culmination of Micron’s innovation for growers. Specifically aimed at cereals and other narrowly planted crops such as onions and carrots, the sprayer features a 6.2 metre hydraulically folding toolbar with ground following carriages fitted with the new innovative Varidome 100HiFlo spray shields. The machine on display will have eleven carriages with triple configuration shields which will boast a patented double membrane skirt around the base. Being revealed for the first time, Micron’s unique double membrane has an inner section that prevents spray coming into contact with the outer section and being transferred onto the crop. Furthermore, the outer layer of the membrane is tapered each end to push the crop away from the area being treated, thus further minimising the risk of crop damage. Proving their DRT (Drift Reduction Technology) credentials, these innovative shields have attained the prestigious 3 star accreditation from LERAP – the highest rating achievable in the UK.

The working width on each individual hood can now be easily adjusted to spray bands from 100mm to 450mm wide which makes the sprayer suitable for work in a wide range of applications and crop stages.

Visitors will also be able to see the recently developed Varidome S3 Hybrid mounted on Micron’s new Modular Tank System. The machine on display will be specifically configured for inter-row herbicide application in asparagus and feature a hydraulically-folding boom fitted with a combination of rigid, fixed position hoods (Varidome 170HiFlo) and circular, freely rotating shields on a breakaway mechanism (Varidome UD600HiFlo) to allow users to spray right up to the base line of the crop. With the boom width of 3.6m, the sprayer can treat two asparagus beds at a time.

However, the appeal of Micron’s innovative Modular Tank System does not end here. Thanks to its highly flexible design, the chassis can be mounted with a number of Micron sprayers including shielded equipment for banded weed control, CDA atomisers for low volume overall spraying or air-assisted spray heads for foliar treatments. As such, the same platform can be successfully used for herbicide, insecticide or fungicide applications in a whole host situations including arable and vegetable row crops, vines and orchards to name but a few.

In addition to its latest innovations, Micron Group will be exhibiting the Weedswiper, a non-drip weed wiper for weed control in grassland and environmentally sensitive areas, as well as a range of equipment for manual applications.