Spraytrac II GPS Track Guidance System

The Micronair Spraytrac II GPS track guidance system is designed specifically to provide precision guidance for ground vehicles used for the control of locusts and other migrant pests. Incorporating a software package and guidance unit, the system enables the driver to follow parallel spray tracks whilst recording the position of the vehicle and the status of the sprayer. Spray jobs can be exported as shape files to allow access on an office or laptop computer. These export files are suitable for upload and use in FAO’s RAMSES software as well as other GIS software packages.

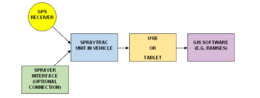

The system consists of two main parts:

Spraytrac II Guidance Unit

The Spraytrac II system provides guidance to the driver via the dashboard-mounted screen. The Micronair ruggedized tablet display can be used, or the software can be run on any android compatible phone or tablet device.

The software provides a very simple familiar user interface to other smart phone and tablet applications. Operation of the system is via an on/ off switch and the device’s touch-sensitive screen.

During operation, an artificial horizon is displayed with parallel spray tracks. These indicate the correct spray path to follow to avoid under- or over-dosing of product. Vehicle position is continuously logged during the spray operation.

The log file of each spray operation can be retained in the memory of the unit or can be stored on an external USB drive (if connected).

Text on the Spraytrac display is available in English, French, Arabic, Russian and other languages by menu selection.

Spraytrac II software

The Spraytrac II software is pre-installed on the Micronair ruggedized IPS LCD touchscreen tablet or can be downloaded onto any android compatible phone or tablet device.

The software provides the following functions:

- Ability to set A-B line and track spacing for generation of parallel lines to follow on the screen

- Real-time position cursor to aid the operator in remaining aligned to the current track

- Return point logging so that if spraying is stopped and the spray block left for any reason (re-filling of the pesticide tank, refuelling etc.) then the operator can easily return to the point where the job was paused.

- Entry of operational data including vehicle registration, operator, product being applied, active ingredient used and application rate

- Generation of shape files with spray control operation information. These are suitable for import into FAO’s RAMSES platform or other GIS software

Specifications

| Electronic Controller Unit (‘Black box’) | |

|---|---|

| Dimensions: | 134mm W x 130mm H x 41mm D |

| Weight: | 0.3kg |

| Operating temperature: | -40°C – +85°C |

| IP Rating: | IP67 |

| Sprayer interface: | Optional connection to Micron vehicle-mounted sprayers to allow geospatial recording of spray treatments |

| GNSS Receiver | |

|---|---|

| Dimensions: | 23mm W x 25mm H x 13mm D |

| Differential correction: | GPS (WAAS, EGNOS) and GLONASS |

| Update rate: | 10Hz |

| Optional Touch Screen Display Unit: | |

|---|---|

| Dimensions: | 235mm W x 146mm H x 13mm D |

| Weight: | 0.56kg |

| Mounting: | By adjustable bracket on suction pad |

| Operating temperature: | -20°C – +60°C |

| IP Rating: | IP67 |

| Display: | IPS LCD capacitive touch screen, full colour display, screen optimised for viewing in direct sunlight and low light |

| Wiring Loom: | |

|---|---|

| Power connections: | 12V cigarette lighter connection fitted with 8-amp fuse, USB power connection for Android device |

| Data connections: | Sprayer interface connection, Black box 30 Way Cinch connection (1 x A-K Block Key), USB storage device connection |