Micronair AU5000 Rotary Atomiser for Aerial Application

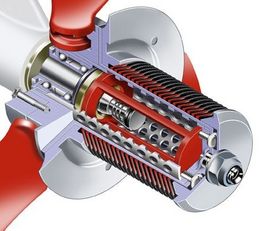

A result of decades of experience in the development of rotary atomisers for agricultural aircraft, the AU5000 atomiser has been precision engineered from proven chemical resistant materials and uses a rotating woven wire gauze cylinder to produce spray droplets.

This technique ensures a narrow, controlled spectrum of droplet sizes for the most efficient and economical application of a wide range of chemicals at low spray volumes to maximise productivity and reduce costs.

The atomiser is driven by the airflow from the aircraft by three highly efficient fan blades. These are adjustable in pitch, enabling the rotational speed to be varied as required. The size of the spray droplets is determined by the rotational speed of the gauze. The atomiser can therefore be set to produce the correct droplet size for a particular operation by a simple adjustment of the blade angle.

Versatile and simple to install

With flow rates of up to 23 litres per minute, the same AU5000 installation can be used for a wide range of output rates from ultra low volume (ULV) to conventional application at 20 – 50 litres/hectare.

The light weight and low drag of AU5000 atomisers enables them to be fitted directly onto the standard spray booms of most agricultural aircraft without any structural modification. Alternatively, quick-change replacement boom kits are available for popular types of aircraft and special installation kits can be supplied for some non-agricultural types.

Every atomiser is supplied with a complete installation kit including a mounting clamp with shock bushes for anti-vibration, diaphragm check valve and secondary valve for instantaneous shut-off, variable restrictor unit (VRU) for simple “dial-up” flow control and all necessary hoses and fittings.

Precise flow control

The flow to each atomiser is controlled by a variable restrictor unit (VRU). This provides finger-tip control of the flow by the simple turn of a knob and eliminates the need to dismantle or change individual restrictor orifices.

VRUs are supplied with fittings and adaptors for the standard nozzle outlets found on most booms. This eliminates the need for any special pipework or modification of the boom.

Overall flow from the aircraft is regulated by the boom pressure in exactly the same way as a conventional spray system.

Optional Atomiser RPM to GPS Interfac

The AU5000 is compatible with the optional Micronair RPM Indicator to GPS Interface which measures the rotational speed of up to ten atomisers and transfers this data to any compatible* GPS guidance system via a serial (RS-232) port. Atomiser RPM is shown on the GPS display screen and can also be included in the GPS log file. Logged RPM can be reviewed after flight alongside other application parameters using the GPS log replay software.

*Consult your GPS system supplier for compatibility details. Both the GPS processor and the PC based log replay system must be running the necessary software. The GPS system unit must have one free serial port.

Suitable for helicopters

AU5000 atomisers are ideally suited for use on both fixed-wing aircraft and helicopters operating at speeds of 145 Km/Hr (90 MPH) and more. Special longer fan blades are supplied for speeds below 160 Km/Hr (100 MPH).

Micronair AU5000LD and AU5000LG Atomiser Assemblies

The Micronair AU5000 can also be fitted with the LD (stacked disc) or LG (mini gauze) interchangeable atomiser assemblies that permit the use of larger spray droplets compared with the standard gauze.

Benefits:

- Low volume spray means increased productivity and reduced costs

- Controlled droplet size for better chemical efficiency

- Drift control through droplet size selection

- Wide flow range

- Wind driven to eliminate the need for auxiliary power

- Easy to clean

Downloads

AU5000 Brochure (English) (PDF 248 Kb)

AU5000 Brochure (Español) (PDF 250 Kb)

AU5000 Brochure (Français) (PDF 250 Kb)

AU5000 Brochure (Português) (PDF 249 Kb)

AU5000LD Brochure (Português) (PDF 383 Kb)

AU5000 Brochure (Русский) (PDF 283 Kb)

AU5000 Manual (English) (PDF 626 Kb)

AU5000 Manual (Português) (PDF 496 Kb)

AU5000LD Manual (Português) (PDF 456 Kb)

AU5000LD Conversion Kit Document (PDF 129 Kb)

AU5000LD Presentation (PDF 3433 Kb)

AU5000 in forestry (PDF 2322 Kb)

Micronair Aerial Product Range Brochure (English) (PDF 1419 Kb)

Boom Clamp Dimensions & Templates (PDF 337 Kb)

New developments in rotary atomisers for improved drift control (PDF 1025 Kb)

Public Health Catalogue Micron-IK (English) (PDF 3578 Kb)

Public Health Catalogue Micron-IK (Español) (PDF 2300 Kb)

Public Health Catalogue Micron-IK (Français) (PDF 2301 Kb)

Public Health Catalogue Micron-IK (Português) (PDF 2894 Kb)