Micronair Industrial Atomiser for Spray Applications

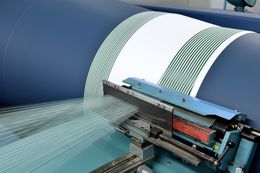

The Micronair direct drive atomiser unit has been designed to meet the exacting needs of industrial applications in the areas of humidification, air cooling, dust and odour control and disinfection.

Using rotary centrifugal energy, the units atomise liquid into precisely controlled droplet sizes. With adjustable RPM control, a droplet size range matched to your application can be selected- reducing wastage to both under- and over-sized droplets.

The Micronair direct drive atomiser offers a low maintenance option for spray generation. No small orifices are required by the systems, reducing the chance of blockage and emergency shutdowns. Through this quality nozzle wear is also not an issue, eliminating losses to poor spray quality and reducing maintenance costs. The continuously rated brushless motors employed also ensure long, maintenance-free operation.

Consuming under 300W of power and with flow rates of up to 180 l/h possible, the direct drive atomiser requires no high-pressure liquid lines or compressed air making installation and maintenance simple.

An air circulation fan and cowl are also available, to provide efficient dispersal of the spray produced by the direct drive atomiser.

Applications in:

- Humidification

- Air cooling

- Odour and dust control

- Disinfection

Benefits:

- Low maintenance atomiser

- Continuously rated motors for long, maintenance free operation

- Precisely controlled spray particles

- Low energy requirement (<300 watts/unit)

- Applications at both high and low volumes supported

Humidity Control

Humidity control is an important factor in many different situations. In an industrial setting, humidification prevents deterioration of stored products as well as reducing the build-up of static electricity. With the correct humidity for a given application scrappage rates can be reduced, in addition to preventing unnecessary shutdowns due to material breaks.

Humidification is also necessary to maintain humidity at comfortable levels for human comfort, with the optimum range being 40-60% RH (Relative Humidity).

The Micronair direct drive atomiser is suitable for use for both direct in-room humidification and as part of complete HVAC systems.

Air Cooling

The Micronair direct drive atomiser provides evaporative cooling by absorbing heat from the air to evaporate the generated spray droplets. The precisely controlled spray particles produced by the unit ensure efficient use of water and avoid the fall out of spray and wetting of surfaces.

Other common spray generators for air cooling use very small orifice nozzles and liquid at high pressure, leading to increased costs for both pumping and maintenance due to the risk of blockage and nozzle wear. Requiring neither high-pressure supply nor any small orifices, the Micron direct drive atomiser offers a competitive alternative to conventional systems.

The Micronair direct drive atomiser offers opportunities for both direct and indirect evaporative cooling and can be used as standalone units or built into larger HVAC systems.

Odour Control

In both outdoor and indoor environments, the Micronair direct drive atomiser can be used for dispersal of odour control products. These are commonly used to combat odours created by industrial and organic waste effluent at locations including landfill sites, waste treatment plants, Energy from Waste (EfW) sites, farm poultry and pig rearing units amongst many others.

Its low power requirements and ability to operate efficiently at low volumes make the unit perfect for mobile units with the same benefits also applicable to any static odour control systems.

Disinfection

Micronair direct drive atomisers can also be used for dispersal of disinfectants to cleanse air of airborne bacteria or disinfect surfaces with biocides. All materials used in the direct drive atomiser are designed to be compatible with aggressive disinfectants.

Downloads

Micron Industrial Atomiser Range Flyer (English) (PDF 8776 Kb)

Micron Industrial Atomisers – Odour and Dust Control Flyer (English) (PDF 3632 Kb)

Micron Industrial Atomisers – Humidification and Cooling Flyer (English) (PDF 3869 Kb)

Micronair Industrial Direct Drive Atomiser Manual (English) (PDF 2517 Kb)